MeChanICs

MeChanICs – Marie Curie Linking Industry to CERN collaboration was the key ingredient in Finland’s involvement in the CLIC R&D programme during years 2010-2014. The MeChanICs Industry Academia partnerships and Pathways (IAPP) platform for precision manufacturing knowledge exchange gathered five manufacturing companies (Loval Oy, Metso Minerals Oy, Tarkmet Oy, Lewel Group Oy and Mectalent Oy) together to enhance their existing research and technology development efforts with Helsinki Institute of Physics and CERN.

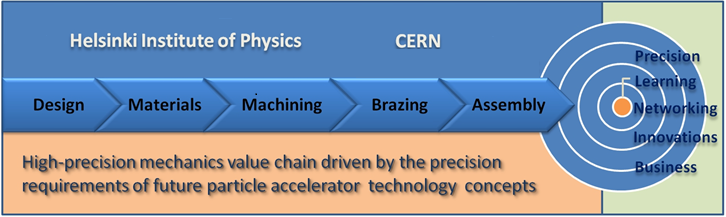

The mechanisms used for the transfer of knowledge within MeChanICs were two-way intersectoral secondments and dissemination workshops. Close co-operation with academia and industry is vital in devising and industrialisation scheme that enables the mass production of the components required to CLIC at an affordable price and according to a stringent timeline. The scientific and technological objective of MeChanICs was to contribute at the early stage of the technical design phase of CLIC. Here the main focus was to show technically how a multi-TeV CLIC can be built with the reasonable cost.

If built, CLIC will require a very large number of parts and components but as it is still in development phase the number of orders have been relatively low and focused mainly for experimental testing and quality assessments. CLIC is continuously searching for new partners that would be interested and capable to participate in the development and manufacturing of the challenging components and structures.

It is here that MeChanICs stepped into the branch, ensuring effective and sustainable future co-operation in the manufacturing of the collider components. The project provided the necessary networks and connections to overcome communication issues. The industry has the knowledge and experience of doing large scale productions to a much larger extent than research institutes, where the focus is on making working prototypes.